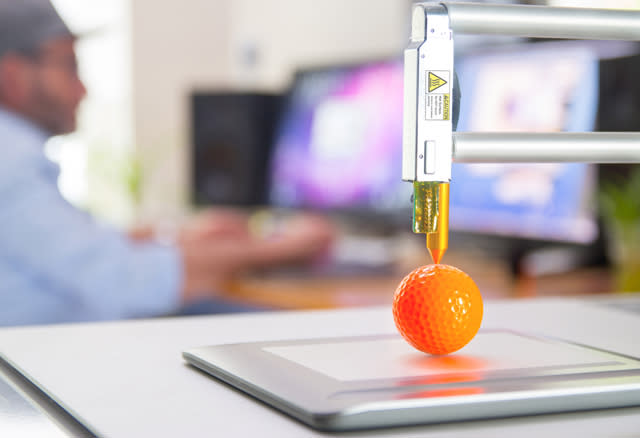

Where Does 3D Printing Go From Here?

3D printing has started to take over the world, revolutionizing the prototyping process and putting more tangible parts in the hands of any user with design software and a few dollars to pay for raw materials. In 2016, it was estimated to bring in $7.1 billion in revenue, with that number expected to triple by 2020. However, the technology is still in its infancy. Over the course of the next decade, we'll see 3D printing come into its own and evolve in new directions we can only currently imagine.

But what might those directions look like? How can we expect 3D printing to develop in the next several years?

Newer Materials

For starters, most 3D printing applications use different types of plastics like ABS and PLA, or epoxy resins to produce materials. These raw materials are relatively inexpensive, malleable, easy to melt, and can produce reliably solid finished products. However, they still have a limited range of application. More specific applications, like custom metal work or electrical components, require niche-specific materials and quite possibly, more precise or different machinery to get the job done. In the next few years, we'll start to see the development of machines that can produce steel, aluminum, semi-conductive, or even more foreign substances reliable and efficiently.

Nano Printing

You might be able to print a fist-sized gear or an inches-tall sculpture for a quick repair or your own amusement, but there's a limit to how small most modern 3D printers can print. The future will likely give us machines that can print products on micro-meter scales, opening up a world of opportunity, especially with biomimicry technology; for example, printing nano-sized structures could enable us to make plastics that mimic the effects of tarantula hairs, spider silk, salamander toes, or other impressive animal parts we barely understand. Nano printing could also lead us to some interesting developments and treatments for medical conditions, including 3D printed injections that function in the bloodstream—like nanobots, which have been predicted as a development for decades.

More Affordable, More Portable

Looking at some simpler developments, it's likely that 3D printing overall will become more affordable and more portable for consumers. Today, even the most affordable 3D printers cost at least a few hundred dollars, and more expensive equipment is gargantuan and fixated to one spot. This is prohibitive for consumers looking for prototyping, part replacement, or other common 3D printing applications. However, in the near future, we may see printers small enough to carry in a briefcase, and cheap enough for almost anyone to afford. Alternatively, we may see the rise of more 3D printing "stations" that allow consumers to print individual objects for a small fee. In any case, 3D printing will be more available and affordable.

Medical Applications

Let's not forget one of the biggest awe-inspiring, futuristic potential applications of 3D printing—the medical industry. Imagine being able to 3D print a replacement organ or a lost limb, which functions exactly the way the original did. You may even be able to print objects and bodily creations that enhance what human beings are capable of, turning us into kinds of cyborgs or otherwise "enhanced" human beings. The key here is being able to print in materials that the human body would be able to accept, and on scales that would allow for tremendous precision. Though cheaper, more available 3D printing is right around the corner, this development is still likely decades away.

Integration

Right now, 3D printing exists as a separate entity entirely. When a machine goes down and we need a replacement piece, we can head to the printer, create that piece, and replace it ourselves. But what if the machines of our future came equipped with their own, automated 3D printing mechanisms, so the machine could 3D print its own replacement part and keep itself working? That's one future imagined by 3D printing technologists. Integrated 3D printers would allow our technologies to keep working indefinitely, constantly refined and updated with better parts and corrected pieces so we never have to worry about repair—and maybe never worry about replacement, with physical updates subbing in for software updates in other modes of technology.

So how long until we're living in an era where 3D printing is inexpensive and, for lack of a better term, normalized? Well, through 2020 we'll probably see steady growth here, with more affordable, usable forms of the technology and a collection of new materials to use. But for more forward-thinking applications, like medical technology or nanobots, we're still many years, and probably decades away. It will be an interesting journey, but eventually, 3D printing may be everywhere, printing literally anything you can imagine for barely more than the cost of raw materials.