MIT’s color-changing ink could let you customize your shoes

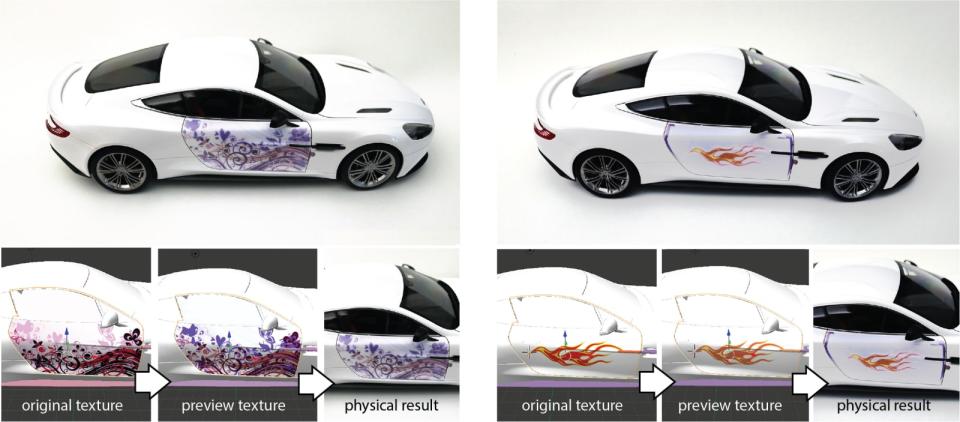

The PhotoChromeleon Ink could let you customize cars and other objects, too.

Imagine if, rather than buy your favorite shoes in blue or red, you could buy one pair of shoes and change the color depending on how you feel each day. Maybe you'd decide to add multicolored flames or zebra print. A new, reprogrammable ink might let you do just that. PhotoChromeleon Ink, developed by MIT's Computer Science and Artificial Intelligence Laboratory (CSAIL), can change the color or pattern of an object when exposed to UV light.

The CSAIL team mixed cyan, magenta and yellow photochromic dyes into a solution that they spray on objects -- anything from shoes to cars, phone cases and toys. A coated object is then placed in a box with a projector and UV light. Users map the color or pattern they want into a program, which uses the UV light to activate and deactivate different colors. The colors last in natural light, and if you aren't happy with the design, you can use the UV light to erase it and start again. For objects the size of a shoe or a model car, the process can take between 15 and 40 minutes.

"This special type of dye could enable a whole myriad of customization options that could improve manufacturing efficiency and reduce overall waste," said CSAIL postdoc Yuhua Jin, the lead author on a paper about the project. "Users could personalize their belongings and appearance on a daily basis, without the need to buy the same object multiple times in different colors and styles."

To create PhotoChromeleon Ink (a play on its chameleon-like nature), the CSAIL team built off its previous ColorMod system, which 3D-printed items that can change color. Each pixel had to be individually printed, though, so the final result was low-resolution. And each pixel could only have two states (transparent and its own color), so color schemes were limited. In comparison, PhotoChromeleon Ink offers high resolution and a wide range of colors and patterns.

The researchers still have work to do perfecting the colors of the dyes, but Ford, which helped fund the CSAIL project, has expressed interest in the ink. The company hopes it might one day cut down on the cost and time required to fabricate automotive parts. "This ink could reduce the number of steps required for producing a multicolor part, or improve the durability of the color from weathering or UV degradation," said Dr. Alper Kiziltas, who specializes in sustainable and emerging materials at Ford. "One day, we might even be able to personalize our vehicles on a whim."