Researchers create bone-inspired 3D-printed building materials

The strong, lightweight polymers have an internal structure similar to bone.

You may not think of your bones as buildings, but researchers do. A team from Cornell University, Purdue University and Case Western Reserve University believes that by studying the internal structure of bones, they may be able to 3D-print stronger construction materials for homes and buildings.

"Bone is a building," says Purdue University professor Pablo Zavattieri. "It has these columns that carry most of the load and beams connecting the columns. We can learn from these materials to create more robust 3D-printed materials for buildings and other structures."

The researchers discovered that the "beams" in bones provide more stiffness and strength than previously understood. Those beams, also known as trabeculae, form vertical plate-like struts and horizontal rod-like struts in bone. In a study published in Proceedings of the National Academy of Sciences, they propose that it's the horizontal struts that increase the fatigue life of bone.

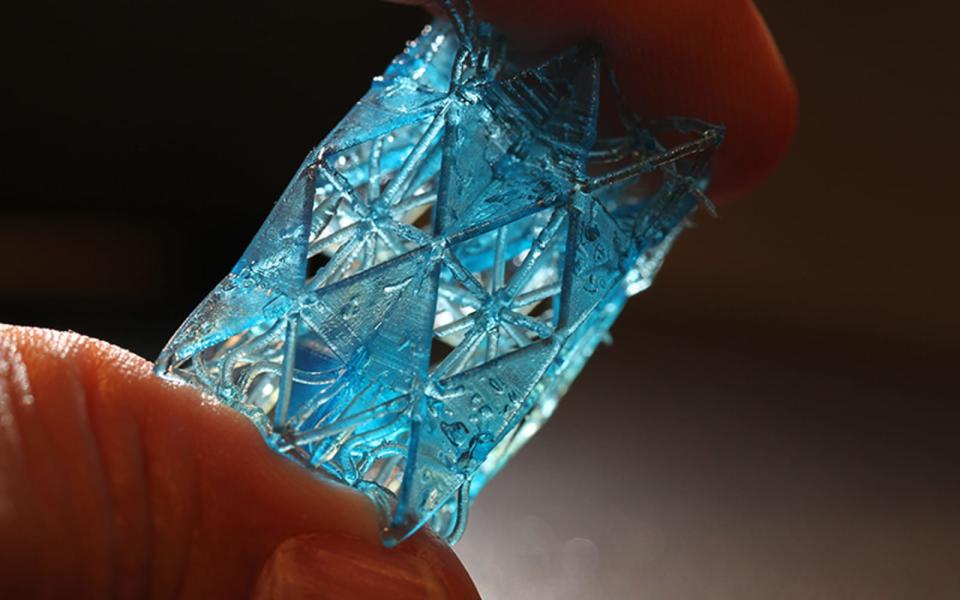

They believe that 3D-printed building materials designed with similar internal structures might lead to more durable buildings. To test the theory, Zavattieri's lab designed 3D-printed polymers with architectures similar to trabecula.

Mechanical analysis simulations found that the thicker the horizontal struts, the longer the polymer lasted under load. Because thickening the struts didn't significantly increase the mass of the polymer, the team believes similar bone-inspired polymers could be used to create resilient, lightweight building materials, and those could be key to creating 3D-printed homes and buildings.