Yale's smart robotic fabric is as flexible as you need it to be

Go from latex rubbery to acrylic hard with the flip of a switch.

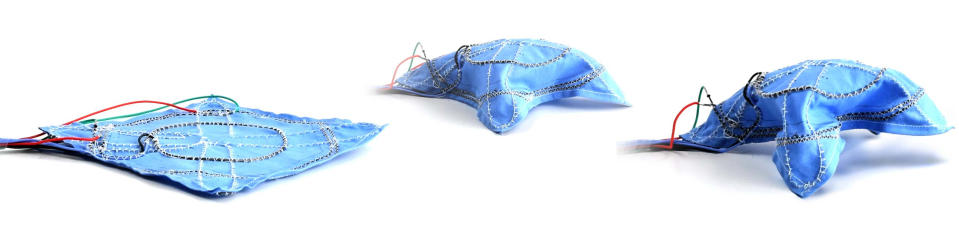

Soft robotics is a rapidly growing field with applications ranging from prosthetics to space exploration. Now a research team out of Yale University has taken the technology one step further with the invention of smart, robotic fabric that can change its shape and stiffness on the fly.

The key to the material’s capabilities lies within the fibers themselves. The team, led by Dr. Rebecca Kramer-Bottiglio, spun epoxy into fibers that can vary their stiffness thanks to the particles of Field’s metal embedded within them. Field’s metal is novel in that it liquefies at very low temperatures. As such when the metal is cool, it remains solid and the fabric is stiff. Applying a low current to the fiber heats the metal slightly causing it to become soft and malleable along with the rest of the fabric.

“Our Field’s metal-epoxy composite can become as flexible as latex rubber or as stiff as hard acrylic, over 1,000 times more rigid, just by heating it up or cooling it down,” lead author Trevor Buckner said. “Long fibers of this material can be sewn onto a fabric to give it a supportive skeleton that we can turn on and off.”

In addition, the team developed a liquid-based sensor to detect changes, either with the wearer or in the surrounding environment, that can be literally painted onto the fabric. They also embedded specially-formed shape-memory alloy wires — which bend themselves into preprogrammed shapes when exposed to current — throughout the material, enabling it to take and hold its proper form. Imagine a pair of smart pants that can help the elderly stand or sit with ease from even the deepest of couch cushions.

Well, the material probably won’t be used for smart pants because the research was funded by the Air Force Office of Science Research which hopes to use the stuff in everything from wearable tourniquets and smart cargo netting to self-deploying tents.