Self-repairing shoes may be a reality thanks to 3D-printed rubber

Self-healing chemistry is good for the sole.

Shoes will invariably wear out with enough use, but scientists might have found a way to delay the shopping trip for their replacements. A USC team has created a self-healing 3D-printed rubber that could be ideal for footwear, tires and even soft robotics. The effort involves 3D printing the material with photopolymerization (solidifying a resin with light) while introducing an oxidizer at just the right ratio to add self-healing properties without slowing down the solidifying process.

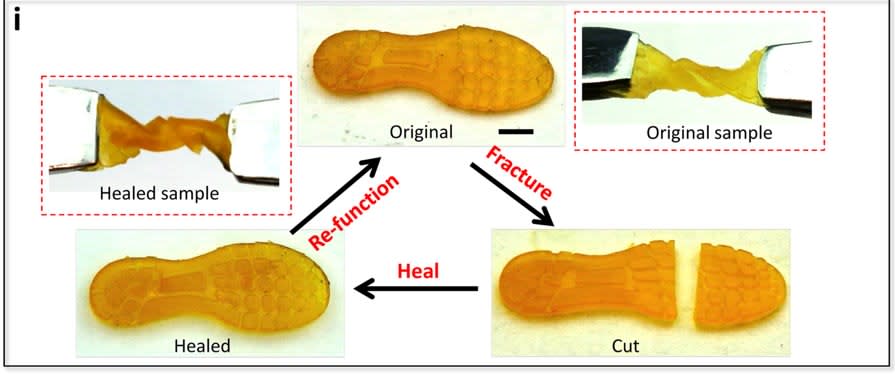

The result is a rubber that's highly durable, but can still be made in a reasonable amount of time. An object that takes 20 minutes to make (such as a shoe sole) can survive being cut in half with a few hours of repair time. And the warmer it is, the faster the material heals. In the lab, it took two hours to fix a cut at roughly 140F.

This might not be ready for the real world in the near future. Researchers would still need to find a way to make this available for mass production. And even if it's ready, it would be important to dial back the hype. This might prevent your shoes from cracking and minimize gouges, but it's not going to keep your running shoes looking brand new after hundreds of trips to the gym. Nonetheless, it could still represent a breakthrough -- and the USC team is working on self-healing properties for harder materials like plastic that could be used in body armor and car parts.