manufacture

Latest

BlackBerry phones are back, baby

The startup OnwardMobility plans to release a 5G BlackBerry smartphone in the first half of 2021.

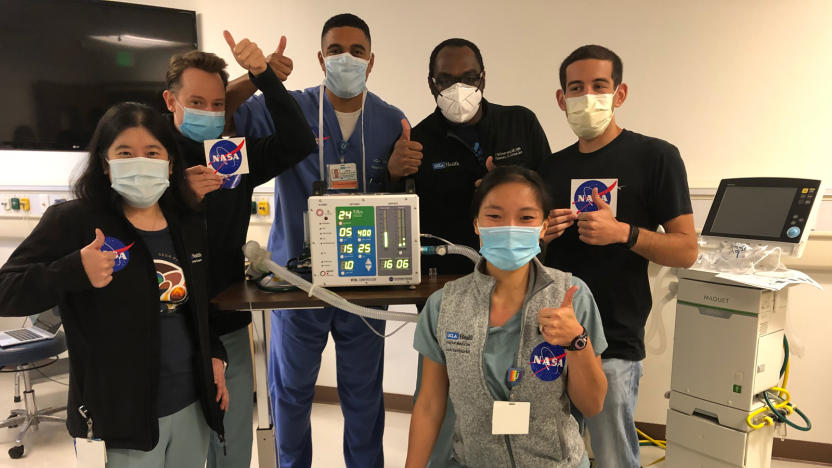

Eight US companies will manufacture NASA’s COVID-19 ventilator

Eight US companies will manufacture the ventilator designed by NASA's Jet Propulsion Laboratory and fast-tracked by the FDA.

Made in America: could your next phone be homegrown?

"Made in America." For some reason, my parents -- and the parents of many of my peers -- take great pride in seeing that phrase. I've seen people buy inferior products just because the label on the back proclaimed that it was thrown together in one of our 50 great states instead of across some imaginary line in "another country." Part of me wonders if people actually check to see if said claims are legitimate. As a business graduate, I fully understand the importance of producing goods within one's borders. There's a delicate balance that needs to be struck between imports and exports, and a huge part of a nation's economic growth hinges on how well that balance is executed. I suspect the generation before mine remembers a very different America than the one I've grown up in -- one where smokestacks outnumbered high-rise buildings, and one where jobs requiring steel-toe shoes were more lauded than those requiring a fancy degree and "knowing the right guy." Manufacturing was the backbone of America through some really, really trying times, and there's some sense of national pride that comes along with images of swinging hammers and climbing ladders. "We built this country," as they say.

Explosion at Apple supplier injures 57 workers

The welfare of Chinese workers is back in the spotlight after an explosion at Shanghai-based Riteng Computer Accessory Company left 23 people in hospital with burns and another 34 with more minor injuries. Local government officials said the explosion happened on Saturday afternoon at a workshop on the fourth floor of the facility. Riteng is a subsidiary supplier to Pegatron Corp and the Chinese newspaper Yi Cai Daily reported it was in the middle of trial production of aluminum iPad 2 back panels. A separate explosion at a Foxconn factory back in Spring was attributed to poor extraction of combustible aluminum dust.

Nokia shows off how it makes the N9, Americans watch with envy

We're not ashamed to say it, we love Nokia's MeeGo-running N9. We love its stillborn (but still awesome) OS, its liquid-looking display and gorgeous machined polycarbonate shell. Now, we can see how that glorious bit of Finnish hardware gets put together in the newly released video seen above. So sit back, relax and let the precision manufacturing wash over you.

Apple hires two camera suppliers for the iPhone 5

Apple has tapped both Largan Precision and Genius Electronic Optical to supply some lenses/camera modules for the rumored upcoming iPhone 5, according to the Taiwan Economic News. Both of the companies have worked on 5 megapixel camera modules that you can now find in the iPhone 4, so it's not too surprising that Apple has gone back to those same sources for what are supposed to be 8 megapixel kits in the next version. And while that seems like good news for Apple, it's also obviously good news for these two companies, who have both earned a 27.5 percent global market share together. If they are contracted for the next iPhone, that share will likely go even higher. Post corrected to clarify that lenses themselves do not carry a megapixel rating.

Explosion at Foxconn's Chengdu plant kills two

An explosion occurred at Foxconn's Chengdu plant earlier today, with reports claiming several workers have been injured. The Taiwanese company has yet to release a statement regarding figures and the cause of this tragedy, but according to 21st Century Business Herald, witnesses saw lightning hit the A05 building before the explosion took place -- it is believed that this is a case of dust explosion, and security guards were allegedly warning evacuees that the smoke was toxic. At the time, hundreds of workers were present in the affected workshop which houses an iPad 2 assembly line. Our thoughts are with the victims and their families. Update: Sina Tech is reporting two deaths and sixteen injured people, with three in critical condition. We've also added a video from the scene after the break, courtesy of Sohu. Update 2: Apple has provided a statement to All Things D, saying: We are deeply saddened by the tragedy at Foxconn's plant in Chengdu, and our hearts go out to the victims and their families... We are working closely with Foxconn to understand what caused this terrible event.

EADS's Airbike is a 3D-printed nylon bicycle, actually looks rather decent

We've seen plenty of neat 3D printing products over the last year or so, though none are as impressive as this bicycle in terms of scale. Unveiled by EADS (European Aerospace and Defence Group), the Airbike is "grown" with nylon powder using a process called additive layer manufacturing, which is similar to 3D printing but with the added benefit of laser-sintering to reinforce the structure. This way the parts can save up to 65 percent in weight while retaining the same strength (of steel or aluminum in this case), and apparently Airbus was quick to pick up this technology well before everyone else (hence named Airbike, in its honor). It's all well and good, except EADS does say there's still some way to go before we can print our own custom Harley-Davidson bikes without breaking our banks. Shame -- as with many things in life, we'll just have to wait.

Why the camera isn't the culprit for the white iPhone 4's delay (update: Woz responds)

Unless you've been away from the Internet over the last few days, you would've no doubt heard about Woz's special appearance at the Engadget Show on Sunday. Unsurprisingly, a few websites ran with some quotes that they pulled from our interview -- specifically, the highlight was Woz "confirming" that the white iPhone 4 was indeed delayed due to camera issues. Well, I don't think this is the case at all. In fact, I'm sure there are plenty of other good reasons for why Apple's been delaying the much anticipated flavor of its flagship smartphone, but the camera just isn't one of them. Head right past the break and all will be explained. Update: Our man Woz has just responded in the comments: I said plenty to make it clear that I know nothing of Apple's reasons for rejecting anything ever. I told how when I got my white iPhone 4 assembled I tested the flash photos and they did indeed have problems. I spoke of testing flash photos versus non-flash ones and comparing flash photos between my white and black iPhones. I don't recall saying that it was a 'reason' Apple rejected the parts although I had read that. For the last part, we were referring to 0:55 in the interview video after the break, but now that Woz has spoken, it could've been a joke at the time that got misinterpreted by some websites. They tend to do that with Woz. Read on!

Exclusive: A day trip to Meizu's factory (video)

Jack Wong is a very lucky guy. Or you can say he's very unfortunate. On one hand, his eight-year-old Meizu label -- literally meaning "the captivating tribe" -- has rapidly become one of the most popular brands amongst Chinese gadget lovers, yet all he's producing right now is just the one phone: the M9. On the other hand, the now-discontinued M8 had notoriously caught unwanted attention from Apple, and even the recent M9 launch saw accusations of Meizu hiring people to stand in line. But the latter points are irrelevant for now -- what we're really interested in is how a teensy MP3 player factory managed to outpace its numerous competitors to become a reputable smartphone maker with a huge fan base. To help us understand what drives the company, we decided to pay Meizu a visit. Go on, you know where to click. %Gallery-115342%

Qualcomm lays down $1 billion for new Mirasol plant in Taiwan, catering small and medium devices

Good news, digital bookworms! After months of rumoring, Taiwan's Ministry of Economic Affairs has just announced that Qualcomm will really be building a new Mirasol plant over there. Specifically, the $1 billion, seven-hectare factory will reside in the Hsinchu Longtan Science Park to mass-produce small and medium flavors of said transflective display, meaning the Snapdragon maker will, for the first time, be able to churn out something smaller than the current lone 5.7-inch model. Yep, those must be the low-power smartphone screens that Qualcomm talked about previously, which sure sound delicious. Now, what's up with our little Pixel Qi?

iPad display supplier reportedly identified

DigiTimes has reportedly identified another iPad parts supplier. This time, Taiwanese electronics manufacturer Coretronic has been pegged to deliver backlighting units (BLUs), starting in the beginning of 2011. Specifically, Coretronic will deliver the units to vendors Chimei Innolux and LG Display. This rumor suggests that the next-generation iPad will not have an OLED display, and will be fundamentally similar to the backlit, IPS-style LCD it currently uses. Last month, DigiTimes suggested that Tripod Technology and TTM Technologies will supply at least the initial run of Printed Circuit Boards for the next iPad, while Taiwanese supplier Largan Precision recently filed documents with the Taiwan Stock Exchange noting that it has been selected as the sole lens module supplier for the iPad 2, with shipments beginning in the first quarter of 2011. [Via MacNN]

Next-generation iPad parts suppliers supposedly named

While we wait for iOS 4.2 to drop, Apple is supposedly busy lining up parts suppliers for the next-generation iPad. DigiTimes reports that Ibiden, Tripod Technology and TTM Technologies will be the initial Printed Circuit Board (PCB) suppliers. Their sources say that these companies have received "certification from Apple" and will begin shipping parts in December. They also expect additional suppliers to be added in February. DigiTimes' track record is hit-and-miss, so keep that in mind. Here's what you can bank on: Apple will update the iPad's hardware. It will include parts, and those parts will be made by someone. The current iPad models will be a year old as of April 3rd, 2011, so it's reasonable that Apple will release an update near the beginning of next year. How's that for a rumor? [Via AppleInsider]

Workers allegedly poisoned while making iPhones

Several Chinese laborers are reporting serious illness after being exposed to a toxic chemical while assembling iPhones. According to reports, the workers inhaled vapors of a chemical called n-hexane while working in a poorly-ventilated room. An ABC News foreign correspondent gained access to the Number Five People's Hospital in Suzhou, where the workers are being treated, to speak with them. They said that n-hexane was being used to glue and polish Apple logos on Apple iPhones that "...they assumed were not fakes." The workers, some of whom have been hospitalized for half a year, state that they became dizzy and eventually were unable to walk. Most report continued pain in their legs. in a similar story, manufacturer Wintek recently halted the use of n-hexane after workers became ill. Wintek makes touch screens for many Apple products. Affected Wintek employees also report chronic leg pain following otherwise successful n-hexane treatment. Wikipedia describes n-hexane as a hydrocarbon that is often "...used in the formulation of glues for shoes, leather products, and roofing. They are also used to extract cooking oils from seeds, for cleansing and degreasing all sorts of items, and in textile manufacturing." It's interesting to note that the Chinese manufacturer is not mentioned in the story. It's well known that Foxconn workers assemble Apple iPhones, and that they have endured their own sets of hardships. To the best of our knowledge, it's unknown if this is about a Foxconn factory, a third-party factory sub-contracted by Foxconn to help meet the incredible demand, a counterfeit plant, etc. We'll follow this story and keep you updated.

Apple number 65 on Newsweek's list of green companies

Newsweek has published their list of the most environmentally-friendly companies, and Apple is ranked number 65 out of 500. While it didn't make the top 10 (Dell is number one), Apple improved significantly from last year when it placed 133rd. The rankings considered a number of scores, including green score, environmental impact and green policies. Other tech companies in the top 10 include HP, IBM, Intel, Sprint, Adobe, Applied Materials and Yahoo!. Apple has made vast improvements in their environmental friendliness over the past few years, as organizations like Greenpeace have put the pressure on. Last January Greenpeace ranked Apple first in their list of the top 18 consumer electronics company in terms of reduction or elimination of hazardous chemicals in the manufacture of its products. [Via Macsimum News]

Taiwanese carriers can't meet iPhone 4 pre-orders

Taiwanese customers placed 200,000 iPhone 4 pre-orders, yet carriers fear that only about one-fourth of those orders will be filled by the end of the year. iPhonetouch.Blorge reports that Apple's three Taiwanese carrier partners, Chunghwa Telecom, Taiwan Mobile and Far EasTone, had access to a mere 1,800 iPhone 4s when they finally became available on September 15th. Additionally, the carriers expect to receive no more than 50,000 units before the year's end. Meanwhile, the chairman of manufacturer Foxconn told the press that his company is pumping out 1.5 iPhones per second -- that's about 137,000 units per day -- to keep up with the enormous global demand. In fact, Foxconn recently bought 1,000 special machining rigs at $20k each to help them stay on track. Most manufacturers own one. Unless they're on Kamino. Remember that "antenna issue" that was supposed to doom the iPhone 4? Um, yeah. [Via Macsimum News]

Foxconn workers to receive 30 percent raise

There's some good news coming from the beleaguered Chinese Foxconn factory this week. Following reports of employee suicides (10 since January of this year), Reuters reports today that production line workers will be receiving a 30% increase in pay, effective immediately. Hopefully this measure will address some of the troubles workers are facing. Foxconn assembles many Apple products, and there was a rumor earlier this week that Apple would begin paying Foxconn workers a percentage of product sales, perhaps 1 to 2 percent, though that was never substantiated. Steve Jobs expressed concern over the suicides at this week's All Things D conference, saying that Apple has people specifically assigned to the case. This factory's troubles started years ago. We first saw a report of Foxconn violating Chinese labor laws back in 2006, admitting that their employees work about 80 extra hours each month -- well beyond the 36 extra hours that Chinese law allows for. In February of this year, a Reuters employer was roughed up by factory personnel while photographing the building. Last month, Foxconn's CEO stated that "we are not a sweatshop," and promised that the company will "soon be able to stabilize this situation." We hope the challenges at Foxconn can be resolved soon. Our hearts go out to the families who've lost loved ones. [Via MacDailyNews]

Self-assembling solar cells built using ancient wisdom, modern technology

Alright, so self-assembling electronics are hardly new in and of themselves, and nanoscale tech tends to always come with bombastic promises, but you don't wanna miss how this latest innovation is built. Two professors from the University of Minnesota have successfully demonstrated a self-assembly technique that arranges microscopic electronic elements in their proper order thanks to the absolute enmity that exists between water and oil. By coating elements with a hydrophilic layer on one side and some hypdrophobic goo on the other, they've achieved the proper element orientation, and the final step in their work was the insertion of a pre-drilled, pre-soldered sheet, which picks up each element while being slowly drawn out of the liquid non-mixture. The achievement here is in finding the perfect densities of water and oil to make the magic happen, and a working device of 64,000 elements has been shown off -- taking only three minutes to put together. If the method's future proves successful, we'll all be using electronics built on flexible, plastic, metal, or otherwise unconventional substrates sometime soon.

Nexus One hardware costs $174.15, US multitouch still priceless

If, while perusing the Nexus One teardown, you were doing a mental tally of just how much each internal part may cost, here's your chance to compare your numbers to some professionally obtained figures. iSuppli reports a preliminary estimate of $174.15 for the cost of materials needed to build each handset. The research firm also congratulates Google on keeping a bill of materials comparable to most recent smartphones while having "the most advanced features of any smart phone ever dissected by iSuppli's Teardown Analysis Service." Costliest of all things was the 1GHz Snapdragon ($30.50), followed by the AMOLED display ($23.50) and memory ($20.40) from Samsung. The Bluetooth and 802.11n WiFi transceiver cost $8.20, and perhaps the most egregious spend was $12.50 on a 5 megapixel camera that many of us might never use. Hilariously enough, Google has spent $17.50 on what is clearly identified as a "capacitive multitouch touchscreen assembly" from Synaptics, though enabling it clearly remains a bridge too far.

Researchers developing OLEDs as cheap as newspapers?

Sure, it'll probably be a good while before you get your hands on an OLED TV, but don't lose heart, young gadget-head! Techno-wizards at the RIKEN center in Japan have concocted a new way to fashion OLEDs that eschews the standard spin-coated films for something called electrospray-deposited polymer films, incorporating "a novel dual-solvent concept" that makes the 'em "smoother than before, thereby enabling [...] superior devices." We'll skip a few details that don't mean anything to those of us who aren't Advanced Materials subscribers (hit the read link for more info) and get to the good stuff: Yutaka Yamagata, the guy who developed this technique, says it will lead to displays "manufactured as inexpensively as printing newspapers." Is that a promise, Yutaka? If so, we're holding you to it. [Via OLED-Info]