nanowires

Latest

Light-emitting silicon overcomes a major obstacle to denser, faster chips

Light-emitting silicon nanowires are finally a reality, opening the door to a new wave of denser and faster chips.

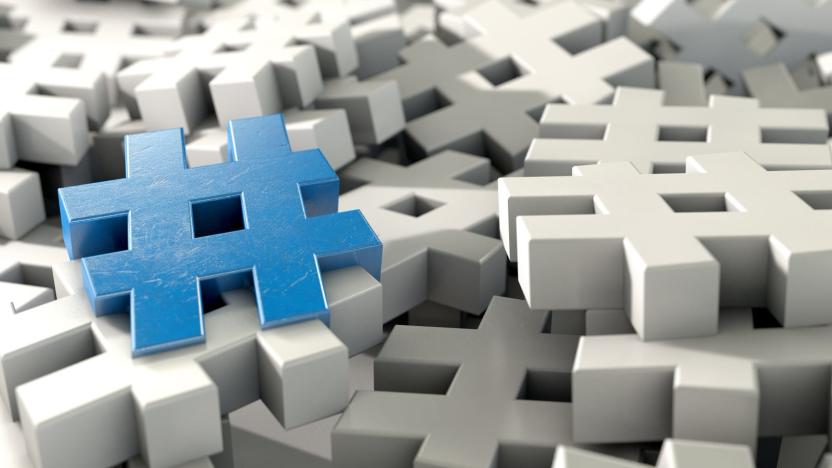

Quantum 'hashtags' may prove the existence of a strange particle

Hashtags could soon be useful for a lot more than fostering discussion on your favorite social network. Researchers have developed a hashtag-shaped quantum chip (shown below) that could confirm the existence of the oddball Majorana particle, which exists as both matter and antimatter at the same time. The team has learned that laying indium phosphide nanowires in the familiar '#' shape creates a closed circuit that lets the particles pass by each other and braid, rather that annihilating each other like they would on a single wire. Think of it like creating streets with intersections instead of a one-lane road -- the 'traffic' can actually get around without collisions.

Six next-gen battery technologies

By Cat DiStasio We all love our battery-powered gadgets, but portable power cells can be devastating to the environment. Fortunately, recent developments have proven that greener batteries are coming in the not-too-distant future. Engineers are replacing toxic components with less harmful materials ranging from leaves to sugar. Other innovations on the rise look to nature to help make batteries last longer, perform better and leave less of a trace once they've been discarded. This gold nanowire-based battery, for instance, was created by accident and could make lithium ion batteries obsolete, while this single-use battery dissolves in water when its job is done, making it easier to reuse its components.

Gene-modified soil bacteria promise eco-friendly computing

You normally need non-renewable elements or minerals to create nanowires. However, the US Navy's Office of Naval Research may have a better solution: the life living in the dirt under your feet. Its sponsored researchers have crafted nanowires from genetically modified Geobacter, a bacteria you find in soil just about everywhere on Earth. The team altered the bacteria so that it would replace amino acids with tryptophan, which is a much better electrical conductor (2,000 times) at the nanoscopic scale. String enough of those bacteria together and you suddenly have wiring that's virtually invisible to the human eye. They wires are tougher and smaller, too, so they stand a better chance of surviving inside electronics.

Nanowires could bring 'tunable' privacy glass to the masses

If you don't want to block light but still need privacy, a discovery from Harvard might let you ditch the window coverings. Researchers at the university's engineering school have developed glass that changes from transparent to translucent at the flick of a switch. Such "tunable windows" aren't new, but commercial models are currently expensive and slow. The new material, however, can transform from clear to cloudy in less than a second and should be cheap to produce.

Nanowire discovery may lead to better, cheaper solar cells

Scientists have figured out a standardized way to make nanowires out of perovskite, a material that could one day make solar energy cheap and ubiquitous. Just a few years ago, cells made from the relatively inexpensive substances had a solar efficiency rating of just 3.8 percent. Fast-forward to 2015, and they can now convert 21 percent of light hitting them to electricity, drawing the attention of scientists and solar panel manufacturers alike. Using nanowires instead of nanoparticles further increases efficiency, because the wires act as "direct conductive highways" to transmit current more efficiently. So far, though, an easy way to build them has eluded researchers.

Stretchable nanowire mesh heats your sore muscles

Don't like having to apply clunky heating pads every time you want to to deal with chronic muscle pain in your arms and legs? Eventually, you might not have to -- that therapeutic care could always be there. Korean researchers have developed a stretchable silver nanowire mesh that heats your joints no matter how you bend them. It's thin enough to fit under your clothes, runs on batteries and maintains a constant temperature, so you could wear the mesh whenever you're out instead of having to wait for prime opportunities to get relief.

Berkeley's artificial photosynthesis turns carbon dioxide into future fuel

Whenever a scientific discovery claims to have solved one of the world's most critical issues, it's hard not to get a little bit excited. Today, our hopes are riding high on the news that Berkeley University might have just worked out how to solve the problem of climate change. Working in collaboration with the Department of Energy and the University of California, researchers have developed a system that captures carbon dioxide and turns it into chemicals that can be used to make plastics, drugs and, even better, biofuel.

Nanotechnology can turn your jacket into a battery

There are certainly clothes and wires that can transmit electricity, but wouldn't it make sense if they could hold on to it as well? Researchers at the University of Central Florida certainly think so, since they've just developed technology that lets wires and threads store energy. Their approach sheathes the wire in nano-sized whiskers that, when treated, become electrodes; the sheath effectively becomes a supercapacitor that preserves energy without hurting electrical transmissions.

Nanowires three atoms wide could lead to paper-thin gadgets

What's that odd shape, you ask? That's the world's thinnest nanowire -- and it could be the key to a future wave of flexible devices. In blasting single-layered, semiconducting materials with an electron beam, Vanderbilt University student Junhao Lin has created wires that measure just three atoms wide while remaining strong and very bendy. Since there are already transistors and memory gates made out of the same material, Lin envisions circuits and whole devices that are paper-thin, yet can stand up to abuse; in the long run, he envisions rollable tablets and TVs that could fit in your pocket. The technique could help produce 3D circuitry, too. We're still a long way from either of those becoming practical realities, but the discovery at least shows that they're technically possible.

Nanowire sensor converts pressure into light, may lead to super-sensitive touch devices (updated)

Outside of pen input, pressure sensors don't get much love these days. However, Georgia Tech has just built an extremely accurate sensor that could give pressure-based devices their due. When a user pushes down on the new invention, its grid of zinc-oxide nanowires emits light that's captured by fiber optics underneath at a very sensitive 6,300DPI. The combination of high resolution with light-speed responsiveness could lead to touch surfaces that capture far more detail than we're used to. While computing interfaces are clearly prime candidates for the technology, Georgia Tech also sees potential uses in pressure-based fingerprint readers and even devices that simulate touch with skin-like behavior. We've reached out to the school for more information regarding its long-term plans, but it already anticipates improving the sensors with more efficient manufacturing techniques. Take a closer look at the sensor after the break. Update: We've since had a chance to follow up, and we're told that commercialization is likely five to seven years ahead.

Plastic skin lights up on contact, may lead to touchscreens everywhere (video)

Flexible circuitry is frequently a one-way affair -- we've seen bendy displays and touch layers, but rarely both in one surface. UC Berkeley is at last merging those two technologies through a plastic skin whose display reacts to touch. By curing a polymer on top of a silicon wafer, the school's researchers found that they could unite a grid of pressure sensors with an OLED screen; they just had to remove the polymer to create a flexible skin. As the film-like material can be laminated on just about anything, it maylead to touch displays in places where they were previously impractical, or even very thin blood pressure sensors. It could also be easy to produce -- since the skins use off-the-shelf chip manufacturing techniques, commercial products are well within reach.

Scientists build soft, transparent contact lens displays with nanomaterials

Of the contact lens display prototypes that we've seen so far, few if any are focused on comfort -- a slight problem when they're meant to sit on our eyeballs. A collaboration between Samsung and multiple universities may solve this with display tech that's meant to be cozy from the start. By putting silver nanowires between graphene layers, researchers have created transparent conductors that can drive LEDs while remaining flexible enough to sit on a contact lens. Current test lenses only have one pixel, but they're so soft that rabbits can wear them for five hours without strain. Scientists also see the seemingly inevitable, Glass-like wearable display as just one development path -- they're working on biosensors and active vision correction. While there's still a long way to go before we reach a cyberpunk future of near-invisible displays, we may finally have some of the groundwork in place.

USC battery wields silicon nanowires to hold triple the energy, charge in 10 minutes

There's no shortage of attempts to build a better battery, usually with a few caveats. USC may have ticked all the right checkboxes with its latest discovery, however. Its use of porous, flexible silicon nanowires for the anodes in a lithium-ion battery delivers the high capacity, fast recharging and low costs that come with silicon, but without the fragility of earlier attempts relying on simpler silicon plates. In practice, the battery could deliver the best of all worlds. Triple the capacity of today's batteries? Full recharges in 10 minutes? More than 2,000 charging cycles? Check. It all sounds a bit fantastical, but USC does see real-world use on the horizon. Researchers estimate that there should be products with silicon-equipped lithium-ion packs inside of two to three years, which isn't long to wait if the invention saves us from constantly hunting for the nearest wall outlet.

New process for nanotube semiconductors could be graphene's ticket to primetime (video)

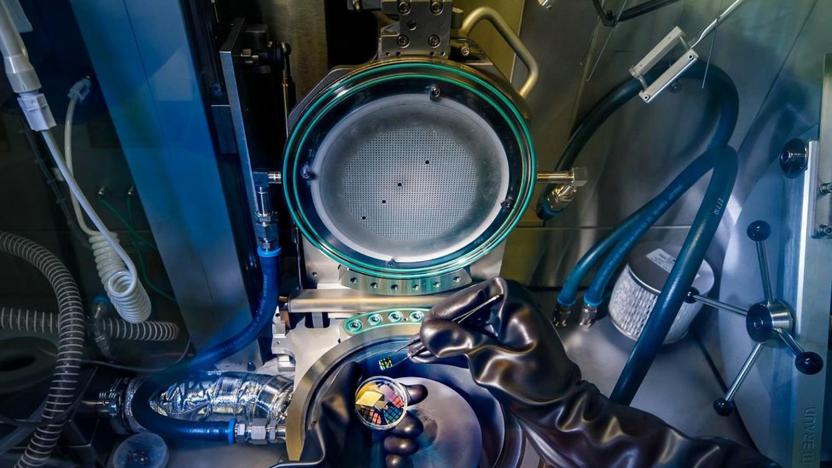

In many ways, graphene is one of technology's sickest jokes. The tantalizing promise of cheap to produce, efficient to run materials, that could turn the next page in gadget history has always remained frustratingly out of reach. Now, a new process for creating semiconductors grown on graphene could see the super material commercialized in the next five years. Developed at the Norwegian University of Science and Technology, the patented process "bombs" graphene with gallium, which forms droplets, and naturally arranges itself to match graphene's famous hexagonal pattern. Then, arsenic is added to the mix, which enters the droplets and crystallizes at the bottom, creating a stalk. After a few minutes of this process the droplets are raised by the desired height. The new process also does away with the need for a (relatively) thick substrate to grow the nanowire on, making it cheaper, more flexible and transparent. The inventors state that this could be used in flexible and efficient solar cells and light emitting diodes. We say forward the revolution.

Harvard scientists grow human cells onto nanowire scaffold to form 'cyborg' skin

Growing human tissue is old hat, but being able to measure activity inside flesh is harder -- any electrical probing tends to damage the cells. But a new breakthrough from Harvard researchers has produced the first "cyborg" tissue, created by embedding functional, biocompatible nanowires into lab-grown flesh. In a process similar to making microchips, the wires and a surrounding organic mesh are etched onto a substrate, which is then dissolved, leaving a flexible mesh. Groups of those meshes are formed into a 3D shape, then seeded with cell cultures, which grow to fill in the lattice to create the final system. Scientists were able to detect signals from heart and nerve cell electro-flesh made this way, allowing them to measure changes in response to certain drugs. In the near-term, that could allow pharmaceutical researchers to better study drug interaction, and one day such tissue might be implanted in a live person, allowing treatment or diagnosis. So, would that make you a cyborg or just bionic? We'll let others sort that one out.

NCSU creates stretchable conductors from silver nanowires, lets gadgets go the extra inch

As often as we've seen flexible electronics, there haven't been many examples that could stretch -- a definite problem for wearables as well as any gadget that could afford to take a pull or squeeze. North Carolina State University's Yong Zhu and Feng Xu may have covered this gap through a form of silver nanowire conductor that keeps the energy flowing, even if the wire is stretched as much as 50 percent beyond its original length. By coating the nanowires with a polymer that traps the silver when solid, the researchers create an elastic material that can crumple and let the nanowire take the strain without interruption. Although the stretchy conductor's nature as a research project could put any practical use years into the future, Zhu notes that it can take loads of abuse, making it a perfect fit for rugged mobile devices. It should also allow for robots with a gentler touch and a more natural look... although we'll admit we're skittish about the creepy androids likely to follow.

Researchers take nanowire transistors vertical, double up on density

3D silicon is all the rage, and now nanowire transistors have further potential to keep Moore's Law on life support. Researchers at A*STAR have found a way to double the number of transistors on a chip by placing the atomic-scale wires vertically, rather than in the run-of-the-mill planar mode, creating two "wrap-around gates" that put a pair of transistors on a single nanowire. In the future, the tech could be merged with tunnel field effect transistors -- which use dissimilar semiconductor materials -- to create a markedly denser design. That combo would also burn a miniscule percentage of the power required conventionally, according to the scientists, making it useful for low-powered processors, logic boards and non-volatile memory, for starters. So, a certain Intel founder might keep being right after all, at least for a few years more.

Copper-nickel nanowires from Duke University could make ubiquitous printable circuits

Nanowires, although they're building steam, still have to overcome the not-so-small problem of cost -- they often have to use indium tin oxide that's not just expensive, but fragile. Duke University has developed copper-nanowire films that could remedy this in style. The choice of material is both a hundred times less expensive to make than indium and is much more durable. It's flexible, too: if layered on as a coating, the nanowires would make for considerably more viable wearable electronics that won't snap under heavy stress. The catch, as you might suspect, stems from the copper itself, which doesn't conduct as much electricity as indium. The nickel will keep your copper electronics from oxidizing faster than the Statue of Liberty, however. Any practical use could be years away, but further successes from Duke could quickly see printable electronics hit the mainstream power and power our dreams of flexible displays.

More efficient heat sinks could sport nanowire whiskers

Sintering is a common process for creating copper heat sinks that involves packing powdered metals into a particular shape and baking it in a vacuum. A funny thing happens though, if you leave out the vacuum part of the equation: you don't get a solid shape, but a porous pile of particles with hollow, nanowire whiskers sticking out of it. The serendipitous discovery could lead to a new way to make heat sinks for everything from CPUs to boilers at power plants. Now researchers at MIT are trying the process with practically every material they can get their hands on. Of particular interest is zirconium, which could be used with fuel rods in nuclear reactors to improve efficiency. The idea of whisker-covered heat sinks may sound strange, but the potential for improving thermal management across a range of applications is huge. Just don't try and pet it -- these things tend to get a little toasty.