Formlabs

Latest

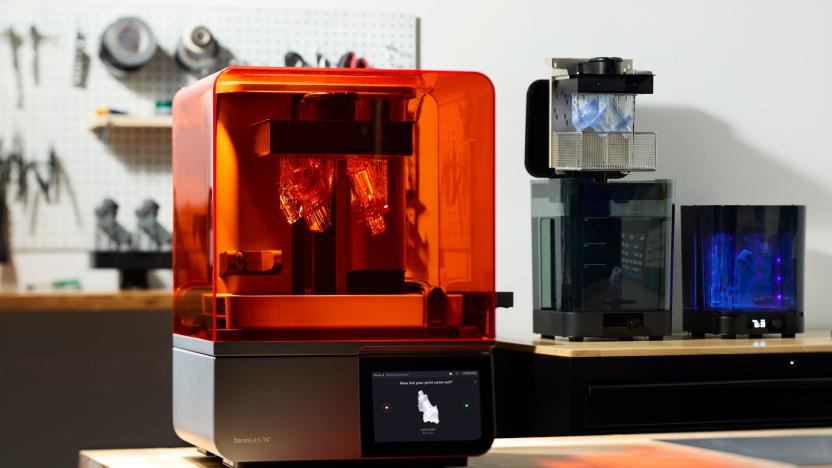

Formlabs' new 3D printers are faster and cheaper to use

Formlabs says its new printers can crank out a prototype in under two hours.

Formlabs shows up at CES 2024 with more realistic 3D-printed teeth

Formlabs' new dental resin can even be color-matched to your existing teeth.

Formlabs' new automation accessories turn its 3D printers into mini factories

Formlabs is adding robotic arms, a storage bin and a bigger resin compartment to turn printers into tiny factories.

Hasbro will 3D-print your face onto its iconic action figures

Ever wanted to become a Power Ranger?

Formlabs’ new 3D printers are 40 percent faster

The new hardware offers 40 percent faster prints, while the new ESD resin is designed to deal with static shocks.

Sennheiser and Formlabs team up on custom 3D-printed earbuds

Formlabs and Sennheiser are working on 3D-printed, custom-fit earbud tips for the German giant's AMBEO earphones.

Formlabs launches its first SLS 3D printer for in-house prototyping

It's for professionals only, with a professional price-tag.

Formlabs' new castable wax makes it easier to 3D-print jewelry molds

Formlabs wants to make itself a key part of the jewelry making process.

FDA clears Formlabs' 3D-printed BiPAP-to-ventilator converter

Formlabs received an emergency use authorization (EUA) from the FDA to 3D-print adapters that can turn sleep apnea machines into ventilators.

Formlabs promises smoother, cleaner 3D printing

Formlabs' 3D-printing technology is now being used to make razor handles, movie props and even false teeth. It makes sense, then, that the products coming out of its printers need to be as smooth as possible to avoid the need for extra finishing. That's the key benefit that the company is touting as it launches two new models, the Form 3 and Form 3L.

Formlabs pushes the boundaries of what 3D-printing can do

When 3D-printing burst onto the scene, its mouth was writing checks its capability had almost no chance of cashing. For all of its grand promises, the results the machines produced were useful for prototyping and very little else. Fast forward a few years, however, and companies like Formlabs have found ways to make the technology far more useful.

Formlabs makes high-quality, automated 3D printing more affordable

Your basic hobbyist 3D printer (technically known as Fused Deposition Modeling or FDM) is great for rapid prototyping because, while the objects it prints are a bit rough, the system and its associated printing costs are relatively inexpensive. However, if you want a more polished and professional-looking product, selective laser sintering (SLS) is the way to go. Problem with that is, of course, that the average SLS 3D printer is roughly the size of a small car and costs anywhere from $200,000 to $5 million. But, there's now a third option. 3D Printer manufacturer Formlabs announced on Monday that it will begin selling a scaled down SLS system that fits on a tabletop and costs 20 times less than other comparable printers.

3D-printed ceramics and metals might finally arrive this year

Remember 3D printing? A couple years ago it was hotly tipped to revolutionize manufacturing, since you could have a whole factory in your home! Except, really, it wouldn't, because spending hundreds or thousands of dollars on a box to make cute plastic doodads wasn't really what most folks wanted. A few years later, having a 3D printer at home is still generally unnecessary, but that may change, and soon. Ish.

Formlabs' Form 2 is all about bigger, better and simpler 3D printing

It's been more than a year since Formlabs debuted its Form 1+ 3D printer, but that was more of a slight revamp of the company's original 2013-era Form 1 printer, rather than a true successor. That honor goes to the new Form 2 printer, which features a similar design to its predecessor, but is far more capable. Its build volume is over 40 percent bigger than the Form 1+, allowing it to produce larger objects, and its laser is 50 percent more powerful for finer resolution printing. The Form 2 also resembles a traditional desktop printer even more now, with the addition of new resin cartridges (you can still manage resin manually, if you'd like). The downside? At $3,499, it's still something meant more for professionals than typical consumers. Existing Formlabs customers will get a slight discount, at least. Form 1 owners will get $400 off the new machine, and backers of the company's original Kickstarter campaign can get $600 off.

Formlabs' second-gen pro 3D printer is 50 percent faster

Formlabs' Form 1 was a top dog among 3D printers when it first shipped, but others have stepped up their game in the past year. It's about time for an upgrade, don't you think? Appropriately, the company has just unveiled the Form 1+, a big improvement to its now-familiar design. The new edition of Formlabs' pro-grade machine is all about raw performance -- a more powerful laser lets it print up to 50 percent faster, and its control system produces finer, smoother sculptures. It should be more reliable, too, thanks to an improved resin tank that better preserves your material.

Formlabs releases PreForm OS X software for its 3D printer

3D printing is set to make the printing industry sexy again for the first time ever. In the next decade, the technology will change the way we acquire simple objects. Earlier this year, Formalbs made waves by raising US$2 million on Kickstarter for its high-resolution Form 1 printer. At the time, the companion software was Windows-only, but now the company has released an OS X versions of the PreForm software, as noted by Engadget. Formlabs made the announcement on its blog: The day has arrived! We've had many requests for a Macintosh-compatible version of our PreForm software, and here it is. Head over to our software page to check out our new OS X-compatible version of PreForm 0.8.4. PreForm on Mac OS X is a first-class citizen and we're releasing it with complete feature parity with the Windows version. Heading forward, we'll release OS X and Windows-compatible versions of PreForm simultaneously. This is our first Apple release and we're still making it better. Help us by reporting any issues, requests, or bugs to support@formlabs.com. The PreForm software is a free download that you can play with now. A Formlabs Form 1 3D printer will set you back $3,300 and ships in November.

Formlabs debuts Mac software for Form 1 high-res 3D printer, adds mesh repair

Somewhere out there a handful of Form 1 high-res 3D printer backers are jumping for joy now that Formlabs has launched a Mac version of its PreForm software. You might remember Form 1 as that project that made a killing on Kickstarter in 2012, raking in over $2 million, or more than 20 times its goal. The 3D model creation program was initially available only for Windows, but the firm will now simultaneously publish updates for both operating systems, starting with this latest release. In addition to support for Apple hardware, version 0.8.4 comes with the capability to automatically patch up holes and irregularities on 3D models, so they can be printed out quickly and smoothly. Both flavors of PreForm are up on Formlabs' website, where the 3D printer itself is available for preorder with a $3,300 price tag and a November 2013 shipping date.

Formlabs ships first Form 1 3D printer, Kickstarter backers should see theirs next week

Some might say it's been a long, long while since October -- with "some" referring to the swath of Kickstarter backers who've been waiting oh-so-patiently for a Form 1 to call their own. Formlabs has just confirmed via a company blog post that the very first Form 1 3D printer shipped out today, as the Collector's Edition Form 1 and half of the Initial Formation tier of pledges hopped on a variety of delivery trucks. The rest of you backers can expect to begin printing "by the end of next week." For those keeping count, the Form 1 is actually a few months behind schedule, but in all honesty, that's pretty good considering the up-and-down nature of crowdfunded projects that manage to find the limelight. The outfit is reminding folks that Form 1 units are shipped as they're produced, fulfilling Kickstarter rewards and preorders by priority. Specifics on group deliveries won't come for a few more weeks, but those in the Bay Area can swing by Maker Faire (or ICFF if you're in the Big Apple) to catch an early glimpse. Oh, and if you're just now hearing of this thing? You can place a $3,299 order right now, but you probably won't get it until July. Them's the breaks, kids!

3D Printing Goes Mainstream liveblog

3D printers might one day be as common as inkjets, letting you conjure up plastic visions of whatever pops into your head. At least, that's the vision of its promoters and there's now a wide variety of models and form factors in the market ranging from sub-$1,000 price tags up to $3-4k for more sophisticated systems. But despite the obvious utility for designers, prototypers and the like, will less demanding users warm to the tech? Join moderator Brian Heater for a discussion of 3D printing's future with Hod Lipson, Professor of Engineering, Cornell University; Max Lobovsky, Co-Founder, FormLabs; and Avi Reichental, President & CEO, 3D Systems. March 16, 2013 1:00 PM EST

The shape of things to come: A consumer's guide to 3D printers

CES 2013 proved to be something of a coming out party for consumer-facing 3D printers. Sure MakerBot earned a fair amount of attention at last year's show with the announcement of the Replicator, which snagged its share of awards from various press outlets. This year, however, saw a relative deluge in 3D-printing representation, with strong showings from 3D Systems, FormLabs, MakerBot and the cloud-based 3D printer, Sculpteo. Even with so many companies rising to prominence, the dream of truly mainstream 3D printing still feels a ways off -- if that is indeed where we're inevitably heading. These nascent days are an exciting time, with a diverse array of companies and organizations vying to be the first to bring the technology to our homes. In a sense, many roads lead back to RepRap, the open-source, community-fueled project aimed at creating a self-replicating machine. As such, the same basic technology underlies many of these devices. At their core, these 3D printers are not unlike their 2D counterparts, offering a way to translate images on computer screens into real-world analogs -- only in this case they're objects you can hold in your hand. Most of these work by melting plastic (largely Lego-like ABS or biodegradable PLA) and squirting it out through extruder heads. The heads operate along the X and Y axes, while the build platform (generally heated in the case of ABS and unheated for PLA) moves downward, allowing the glue gun-like extruders to build up the thin layers of plastic. Some printers rely on other technologies, many of which are rooted in the world of rapid prototyping, a category of fabrication that has been around for decades and used by companies like Boeing and Ford to created scale models of concepts. There are a surprising number of companies and organizations currently invested in the space, be it through pre-fabricated models, kits or open-source, downloadable plans. We pulled together a list of some of the most prominent, which you can check out after the break.